Heavy equipment operations are at the core of industries like construction, mining, logistics, and manufacturing. From cranes and forklifts to excavators and drilling machines, these powerful machines demand skilled operators who can perform with precision and confidence. Traditional training methods, however, often involve high costs, longer training cycles, and significant safety risks. This is why leading industries are turning to VR training as a game-changing solution.

The Shift Toward Virtual Reality in Equipment Training

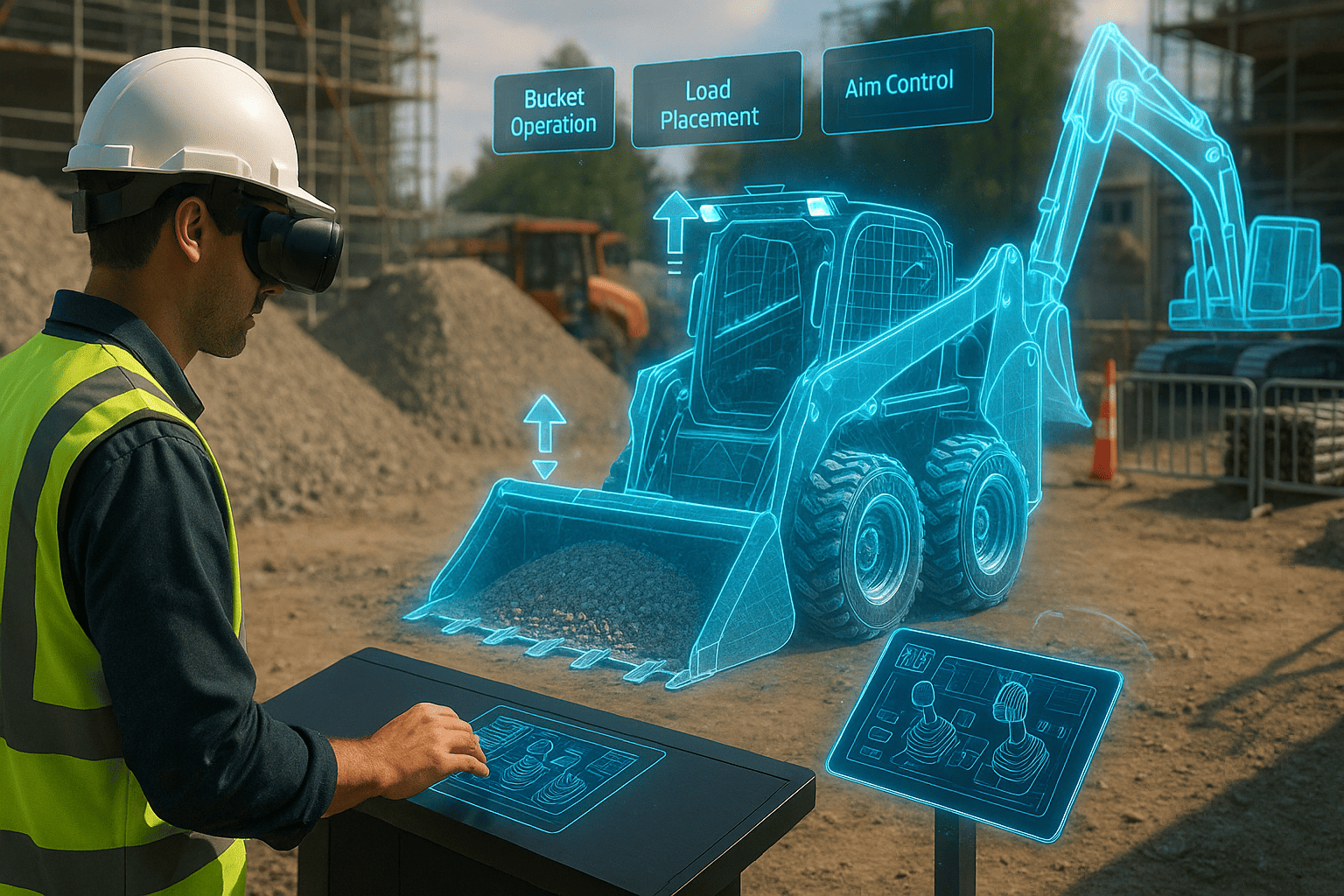

VR equipment training for heavy machinery operators provides an immersive, interactive simulation of real-world scenarios. Instead of learning solely on physical machines, workers can practice in a virtual environment that mimics the complexities of heavy equipment operations. This approach is not only safer but also more cost-efficient and scalable for industries managing large fleets and diverse training needs.

By leveraging solutions from a VR training company, industries are modernizing how they train operators, reducing downtime, increasing workforce readiness, and minimizing the risks associated with hands-on learning on actual equipment.

Key Reasons Industries Choose VR Training for Heavy Equipment

1. Risk-Free Learning Environment

Heavy equipment mishandling can lead to accidents, injuries, and costly damages. With VR training, operators can make mistakes and learn from them without real-world consequences. This makes training safer and builds operator confidence faster.

2. Cost-Effective Training Solution

Traditional heavy equipment training requires significant fuel, maintenance, and machine usage costs. VR training eliminates these expenses, allowing industries to train more operators without the financial burden of running physical machines for practice.

3. Immersive & Realistic Simulations

VR training solution replicate the real-world experience of operating cranes, forklifts, excavators, and other heavy machinery. Operators experience authentic controls, spatial awareness, and scenario-based challenges that prepare them for real tasks.

4. Faster Skill Development

Interactive, repeatable VR simulations help workers grasp complex operations more quickly. Instead of waiting for machine availability or on-site conditions, trainees can practice anytime, accelerating the upskilling and reskilling process.

5. Performance Tracking & Analytics

VR equipment training integrates performance metrics into training modules, tracking response times, precision, and decision-making. This data-driven feedback enables industries to monitor progress and standardize skill levels across teams.

6. Remote Accessibility

With VR solutions, industries can train operators across multiple locations, ensuring consistent training quality without geographical barriers.

The Future of Heavy Equipment Training

As industries continue to embrace digital transformation, VR equipment training is set to redefine workforce development. Companies that adopt immersive training solutions will be able to reduce costs, minimize downtime, and build a highly skilled workforce prepared for the challenges of today and tomorrow.

With its expertise in building cutting-edge VR training solutions, DevDen helps organizations modernize workforce training and unlock safer, faster, and smarter operator development.